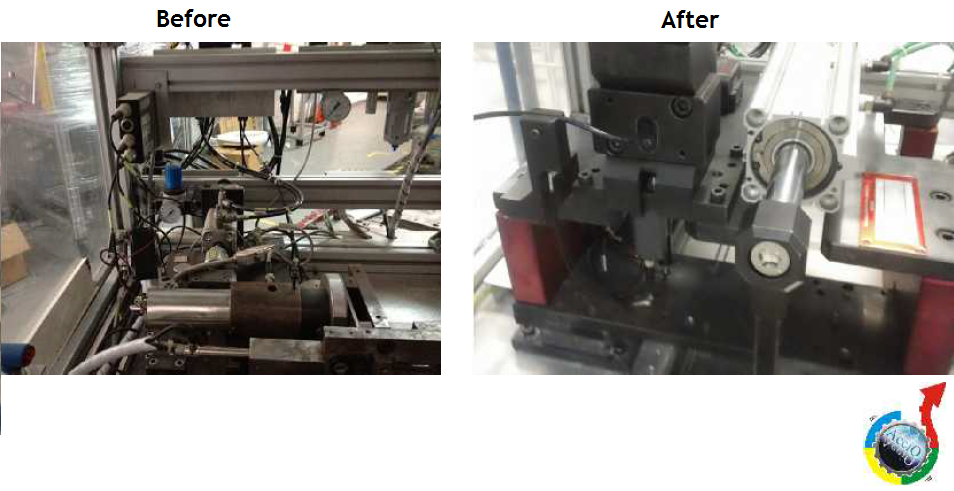

System capable of performing the 2 pieces assembly by insertion at a certain pressure and a millimeter fraction displacement. The system detect desirable conditions of the pieces: Alignment, content, model identification; all through different types of sensors: laser, inductive, optical fiber beam. The control system consists on a MOVIPLC interacting with a MOVIDRIVE, which together control by direct ins and outs the servo-cylinder movements, as well as the operator panel

|

|

|

|